Key to productivity and quality, process control is now a challenge for all industries.

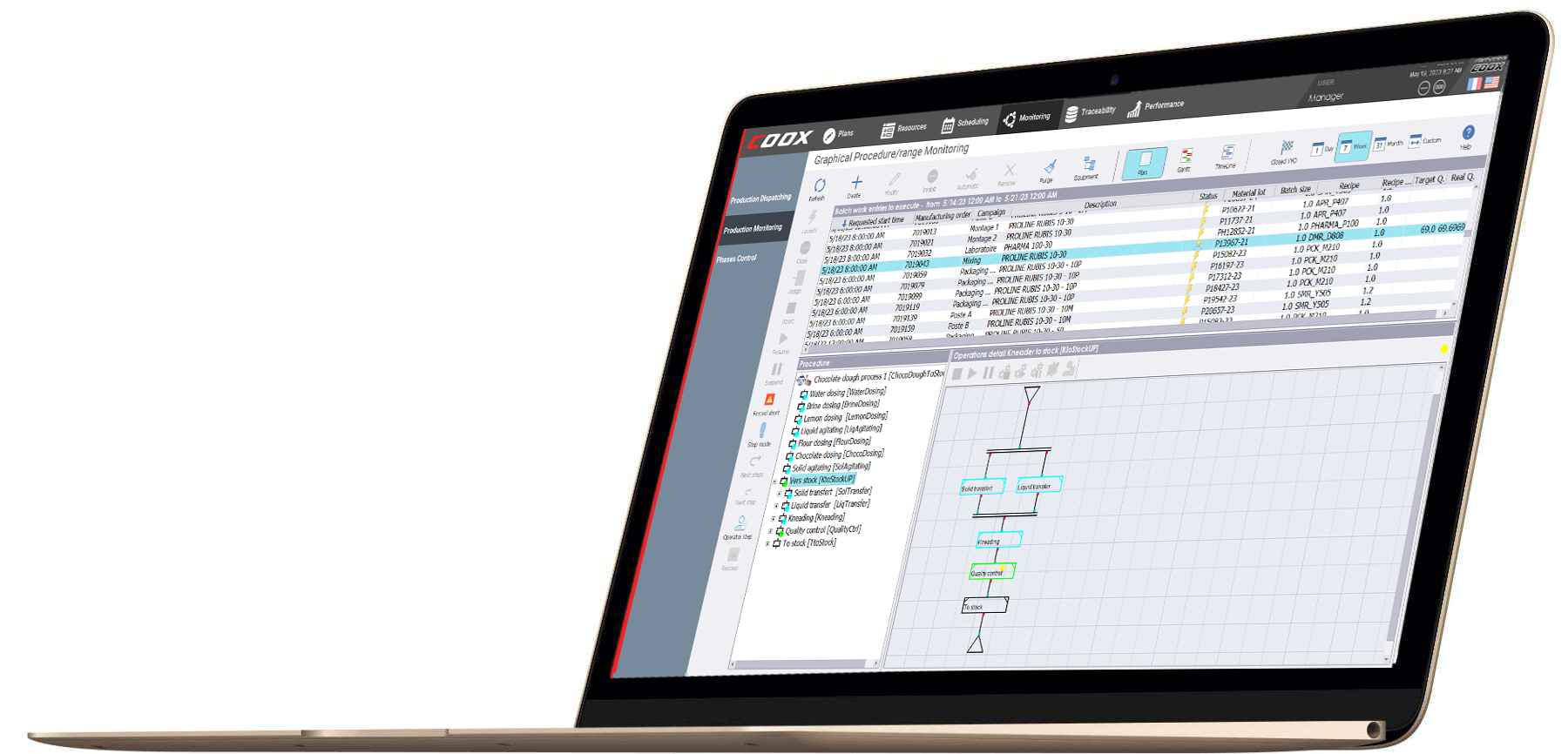

The COOX solution reconciles compliance with the latest ISA-88 and ISA-95 standards with operational efficiency and process flexibility. The customizable ergonomics of the driving components provide immediate efficiency for both line operators and operations managers, as well as natural connectivity to other MESbox of COOX range, such as material traceability or performance analysis.

For the manager

COOX (COllaborative Operation & eXecution) provides a real-time vision of all manufacturing orders in progress: stages completed, in progress, awaiting resources or in error. The successive steps are presented in the form of a simple list or in the form of a graph for the processes implementing steps in parallel. For each step, whether manual or automatic, the start and end dates of execution, as well as all the input or output parameters will be systematically traced.

For the operator

Depending on the current manufacturing order, the list of operations to be performed is displayed and allows the operator by color code to identify themselves in the execution of their own sequence. The manual steps are considerably simplified by the display of maps, photos or videos illustrating the operation to be carried out. Acceptable tolerances are automatically tested by the software and allow self-correction. The execution time of manual operations is perfectly controlled with an optimal level of quality.

Process execution engine and flexibility

Manufacturers often need to optimize the execution of their production process (to execute several orders in parallel, or run several preparatory phases at the same time). They must also be able to react to uncertainties arising during execution, such as unavailable equipment or raw materials. This requires a full-fledged execution engine able to orchestrate your production according to rules you have defined. This type of engine, compliant withe the ISA-88 standard, is a standard feature of our MESbox PMT module.

Direct piloting phases

If required, authorized operators have access to an intuitive interface that instantly provides the phase status of any equipment or section of the plant. It is therefore easy to understand the reasons for stopping the execution and / or to modify parameters of a step in order to allow the manufacturing to continue. However, traceabilitywill not be sacrified : these operations are under the control of COOX execution engine and all operations with their actual parameters will be traced.

Process traceability

Process traceability involves tracing all the process parameters while the process is running. These include the input parameters for each operation (such as the quantities to use, the manufacturing specifications, adjustments, and theorical speeds); the actual parameters for those operations (such as the quantities that were indeed used, actual speeds, or weighs measured); and any events or alarms that occured during the process (such as excessive temperature, motor cut-outs, or insufficient stirring speed). You can record these parameters for each product batch : this is called the batch history or batch file.

Based on the unique concept "Produce, it's traced !", COOX's MESbox PMT module provides systematic process traceability and realizes an electronic batch file without any computer development thanks to the modeling of installation and operations.

Manufacturing history – Electronic batch file

All of the manufacturing execution information is traced on the database of your choice, using the native mechanisms of COOX platform. The MESbox PMT packs them in a synthetic history form, or electronic batch folder, which contains all the useful information attached to a batch : batch properties, list of equipment used to produce it (with start date and end of use), list of process steps performed with their timestamp, setpoint parameters and actual values, and remarkable process events (alarms, operator intervention, etc.) that occured during batch manufacturing. The electronic file may be edited as a report.

CORRESPONDING MODULES OF THE COOX® RANGE

The operating procedures and process monitoring is carried out by MESbox PMT module (Production Management & Traceability) of COOX range.

• Runtime software for batch and discreet processes

• Conformity ISA-88/ISA-95

• Graphic modeling of the process without data-processing knowledge

• Ergonomics of control customizable

• Detailed planning of the work orders

• Traceability of the set points and actual value, batch file

• Automatic quantitative adjustment

• Visualization and piloting since any point of the intranet

• Direct link with the traceability of product

• FDA requirements 21 CFR 11